Introduction

Materials and Methods

Plant materials and a micro oil sprayed thermal air (MOTA) technique

Scanning electron microscope (SEM) Analysis

Measurement of rehydration rate

Color measurement

Statistical analysis

Results and Discussion

Epidermal changes of dried wild vegetables by Micro oil sprayed thermal air (MOTA) technique

Quality changes of dried wild vegetables by Micro oil sprayed thermal air (MOTA) technique

Introduction

Wild vegetables, such as Cirsium setidens, and Aster scaber, are widely cultivated and consumed as daily food ingredients in South Korea. They are also considered a health promotion plant because their extracts show potential pharmacological activities dependent on various antioxidant compounds (Jeong et al., 2008; Noh et al., 2013; Nugroho et al., 2009; Song et al., 2018; Suh et al., 2020). These wild vegetables have been distributed into commercial markets as dried food ingredients because they readily lose their marketability during storage. Drying has been a widely used method to improve food stability during storage to prevent biochemical deterioration and minimize chemical and physical changes (Lewicki, 1998; Lin et al., 1998). Likewise, wild vegetables have a great potential to extend their storage period and shelf-life at commercial markets. However, the rehydration procedure of dried wild vegetables is essential for use as food ingredients, which requires extra preparation time. Inadequate rehydration procedures or time lead to undesirable textural properties of rehydrated food ingredients (Marabi et al., 2006). Meanwhile, pre-drying treatments (e.g., blanching, etc.) are applied in most cases because it has a markedly effect on rehydration ability, color characteristics, textural properties, and flavor of dried fruits and vegetables (Lewicki, 1998). Therefore, developing optimal pre-drying methods is crucial to produce high-quality dried wild vegetables and increasing acceptability to consumers.

To improve the quality of dried fruits and vegetables (e.g., rehydration ability and textural properties, etc.), chemical and non-chemical pre-drying methods have been extensively studied over several decades. Pre-treatment with sucrose and glycerol prior to drying improved the rehydration ability of dried celery (Neumann, 1972). Marabi et al. (2006) reported that vacuum-puffed-dried carrot particulates show higher texture and flavor acceptability than air-dried carrot particulates after rehydration. The sensory quality of dried wild vegetables was improved by pre-treatment with dipping sulfite solution or sulfur fumigation (Hwang and Rhim, 1994). Pinakin et al. (2020) showed that blanching preceded by treatment with potassium meta-bisulfite and citric acid influences the considerable level of physico-chemical and phytochemical contents in dried mahua. However, because sulfite has been considered a potential hazard to health, sulfite treatment on fresh fruits and vegetables was prohibited in 1986 by FDA (Buta et al., 1999). In addition, the textual properties of wild vegetables differ from the fruits and vegetables. Therefore, finding suitable pre-drying and drying processes for wild vegetables has become essential.

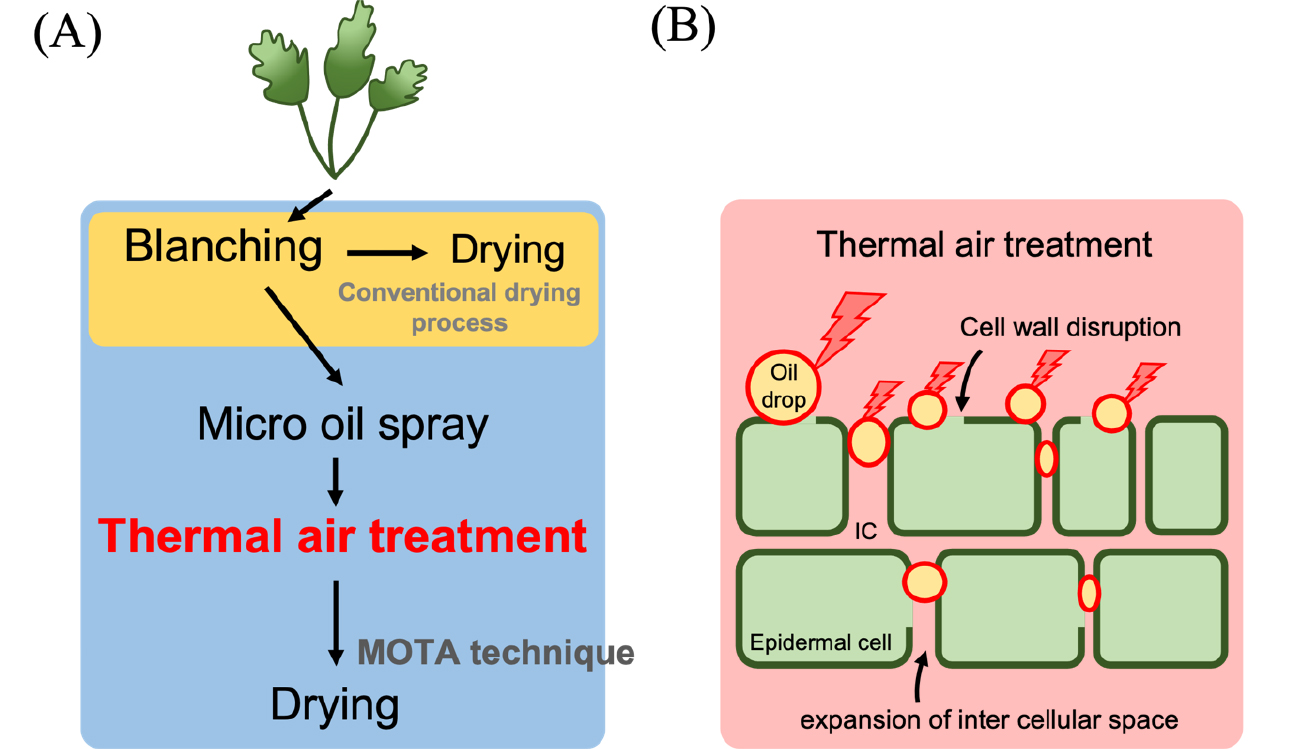

Recently, we developed a new pre-drying method termed as “micro oil sprayed thermal air (MOTA) technique”. MOTA technique is based on disrupting the cell wall by thermal air, leading to softening of plant tissue. Resultingly, a partial cell wall disruption caused by temporary treatment with thermal air prior to drying contributes to improving the rehydration ability and color properties of the dried wild vegetables. Here, we evaluated the advantage of the MOTA technique using two wild vegetables (Cirsium setidens, and Aster scaber) compared to the conventional drying method.

Materials and Methods

Plant materials and a micro oil sprayed thermal air (MOTA) technique

Wild vegetables (Cirsium setidens, and Aster scaber) were grown in a greenhouse (temperature range and cultivation period) in the National Institute of Forest Science, Suwon, Gyeonggi-do, South Korea, and harvested at the commercial maturity stage. The harvested wild vegetables were washed with tap water and then blanched at 90℃ for 3 min. After blanching, the wild vegetables were cooled in cold water immediately and transferred into a spin-dryer to remove residual water. For treatment with MOTA, each sample was sprayed with 0.2% oil and thermally treated using an air-fryer (DAP-I14DAB, Zhongshan Aouball Electric Appliances Co., LTD, Zhongshan, China) at 90℃ for 10 min. Finally, the samples were dried using an agricultural dryer (UDS-2511F, KD Navien, Seoul, South Korea) at 45℃ for 12 h.

Scanning electron microscope (SEM) Analysis

The dried leaves were mounted on the aluminum stubs using a double-sided adhesive conductive carbon disk. All samples were coated with gold using an ion-sputtering device, and all samples were observed using a low-voltage field emission SEM (SU3500, Hitachi, Tokyo, Japan) at an accelerating voltage of 5–10 kV with a working distance of 8–10 ㎜.

Measurement of rehydration rate

To measure rehydration rate, dried wild vegetables (3 g of dried wild vegetables [DWV] and MOTA-dried wild vegetables [MOTA-DWV]) were weighed immediately and then soaked in boiled water for specified time intervals (3, 5, 10, 15, and 30 min). Next, the rehydrated wild vegetables were transferred into a bowl filled with cold water and cooled. The rehydrated vegetables were placed on a sieve overlapped with tissue paper to remove residual water and then weighted immediately to determine the final water content. The final water content of rehydrated vegetables was determined according to AOAC standards (AOAC, 1975).

Color measurement

The color of rehydrated wild vegetables was measured by a Minolta Chroma Meter (Model CR-400, Konica Minolta Optics Inc., Osaka, Japan) at three equidistant points for each sample. To describe color characteristics between treatments, the values were calculated and presented using the Hunter scale: L (lightness), a (greenness < redness), and b (Blueness < yellowness).

Statistical analysis

All data are presented as mean ± standard deviation (SD). To assess the statistical significance of differences between two groups of data, Student’s unpaired t-test was carried out using Graph Pad Prism 9.

Results and Discussion

Epidermal changes of dried wild vegetables by Micro oil sprayed thermal air (MOTA) technique

The plant cell wall is composed of polysaccharides, such as pectin, hemicellulose, and cellulose, which are cross-linked in cell wall layers (Lerouxel et al., 2006). These cell wall components have a more rigid structure after drying, which is responsible for decreased rehydration ability. The water absorption of dried wild vegetables during the rehydration process determines the extent of preparation time and textural properties. The rehydration process needs sufficient time to reconstitute the cellular structure of dried wild vegetables, which contribute to the textural softening of rehydrated wild vegetables. Therefore, enhancing rehydration ability is a major task for utilizing dried wild vegetables more comfortably. A newly developed MOTA technique consists of pre-drying and drying methods, in which oil-spray and thermal air treatments are added to the conventional drying method (Fig. 1A). Heating disrupts and softens plant cell wall tissue (Alvarez et al., 2001; Greve et al., 1994). However, undesirable changes in color and textural properties of final dried plants occur in inadequate heat treatment. Therefore, it is essential to find an optimal heating temperature, period, and a suitable instrument if heating is used in a pre-drying procedure. MOTA technique temporarily exerts thermal air (90℃ for 10 min) on the surface of plants via sprayed oil drops, and it can be expected to disrupt cell wall tissue and expand inter-cellular space (Fig. 1B).

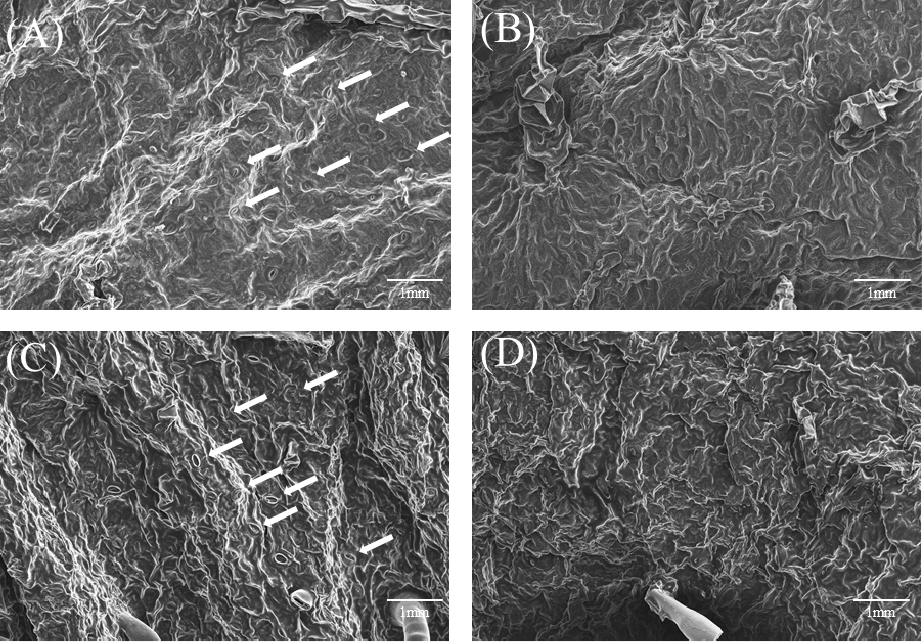

To elucidate the effect of MOTA treatment, we performed a SEM analysis. As a result, multiple stomata (gas exchange pores) were observed in the leaves of DWV [C. setidens (Fig. 2A) and A. scaber (Fig. 2C)], whereas multiple stomata were not observed in the leaves of MOTA+DWV [C. setidens (Fig. 2B) and A. scaber (Fig. 2D)]. These results suggest that MOTA treatment has the effect of destroying multiple stomata.

Quality changes of dried wild vegetables by Micro oil sprayed thermal air (MOTA) technique

The value of rehydration rate is one of the parameters used to determine the quality of fruits and vegetables. First, to examine the rehydration rate of two wild vegetables, dried wild vegetables (DWV) were soaked in boiled water for 3, 5, 10, 15, and 30 min, and then the weight was measured immediately. The rehydration rate of MOTA-DWV for 30 min in boiled water was higher than that of DWV in all wild vegetables (Fig. 3A). Specifically, C. setidens and A. scaber showed a considerable increase in rehydration rate even for 5 and 15 min in boiled water, respectively, comparable to the rehydration rate at 30 min. We estimated the improvement rate of the MOTA technique by comparing the rehydration rate at 30 min between MOTA-DWV and DWV. The highest improvement rate was observed in C. setidens at 154.3%, and A. scaber showed 116.48%, respectively (Table 1). These data indicate that the MOTA technique enhanced the rehydration ability and reduced the reconstitution time to achieve the maximum amount of water in rehydrated wild vegetables compared to the conventional drying method.

Fig. 3.

Comparison of (A) rehydration rate and (B) color characteristics of two wild vegetables processed by conventional method with MOTA technique. Asterisks indicate a significant difference between dried wild vegetables (DWV) and MOTA- dried wild vegetables (MOTA-DWV) according to Student’s unpaired t-test (*p < 0.05, **p < 0.01, ***p < 0.001; A: n = 9 and B: n = 3).

Table 1.

Improvement of rehydration capacity by MOTA technique as compared with conventional method. Asterisks indicate significant difference between DWV and MOTA+DWV according to the Student unpaired t-test (**p < 0.01, n = 3)

Various pre-drying and drying methods affect the rehydration ability of dried fruits and vegetables. Maskan (2001) showed that the microwave-assisted drying method has the advantage of a higher rehydration value of dried slice banana than that processed by the traditional drying method. Ultrasound pre-treatment enhances the drying and rehydration processes of sliced carrot (Ricce et al., 2016). The highest rehydration ratio of sliced tomato is obtained by a heat pump and microwave vacuum drying system (Gaware et al., 2010). These pre-drying and drying methods can be applicable to the production of various dried fruits and vegetables. However, it is possible that rehydration characteristics may be altered by plant species and cut shapes, although plants are subjected to the same pre-drying or drying process. Therefore, it is important to apply optimal pre-drying and drying methods based on the plants and cut shape. In this study, the MOTA technique showed an advantage in the rehydration ability of C. setidens and A. scaber in terms of reducing reconstitution time to achieve the maximum amount of water, suggesting that the MOTA technique is a suitable drying method for C. setidens and A. scaber.

Color characteristics are one of the quality attributes of food ingredients, and the high similarity of color characteristics between flesh and rehydrated food ingredients should increase acceptability to consumers. To compare color characteristics between DWV and MOTA-DWV, dried wild vegetables were reconstituted in boiled water for 30 min, and then the color was measured after blotting residual water with tissue paper and presented using the hunter scale. As shown in Fig. 3B, hunter values of rehydrated wild vegetables were different between DWV and MOTA-DWV. In the case of C. setidens, and A. scaber, Hunter L (brightness) and Hunter b (blueness < yellowness) were not significantly changed between DWV and MOTA-DWV. However, a significant difference in Hunter a (greenness < redness), between MOTA- DWV and DWV was observed in C. setidens, indicating that MOTA-DWV was higher greenness than DWV. These data indicate that MOTA treatment has an effect on the color characteristics of DWV after rehydration in specific wild vegetables, such as C. setidens.

Drying leads to changes in the color characteristics of fruits and vegetables. Because color characteristics are associated with consumer preference, many efforts have been made to improve color characteristics of dried or rehydrated fruits and vegetables. Moreira et al. (2008) reported that rehydration temperature and time have an effect on changes in color characteristics of rehydrated chestnuts, even though the color characteristics were not recovered to the extent of fresh fruits by rehydration. Zielinska and Markowski (2012) showed that the color characteristics are altered by blanching temperature, a pre-drying treatment, and rehydration time. In our experiments, we carried out a branching and rehydration process at a relatively high temperature similar to conventional branching and rehydration conditions of the wild vegetables. However, a difference in the color characteristics between DWV and MOTA-DWV was observed after rehydration in C. setidens, which showed higher greenness. These results suggest that the MOTA technique improves the color characteristics of specific wild vegetables after the rehydration process despite relatively higher blanching and rehydration temperature. Several pre-drying methods showed improved color characteristics by inhibiting enzyme activities (e.g., polyphenol oxidase and peroxidase) related to the phenolic composition (Alolga et al., 2021; Bußler et al., 2017; Sun et al., 2021). In this study, we speculated that changes in color characteristics are partially attributed to cell wall disruption and expansion of intercellular space caused by the MOTA procedure. However, because changes in the biochemical composition are related to the visible color of dried plants, the effect of the MOTA technique on changes in biochemical composition of wild vegetables needs to be further studied.

In conclusion, wild vegetables have been dried as fresh-cut shape after blanching, and those have a different texture to fruits and vegetables, i.e., wild vegetables have a more tough texture than other fruit and vegetable slices. In this study, we evaluated the improvement of the quality of dried wild vegetables processed by the MOTA technique. The rehydration rate of two wild vegetables (C. setidens, and A. scaber) was enhanced by the MOTA technique, and color characteristics were also improved in C. setidens, indicating that the overall quality of rehydrated wild vegetables is improved by MOTA technique. Our finding suggests that the MOTA technique is an optimal method to dry wild vegetables and facilitate the using dried wild vegetables as food ingredients due to improving overall quality and reducing preparation time. The effectiveness and usefulness of various pre-drying and drying methods on wild vegetables need to be elucidated. Likewise, it can be possible that the combination of the MOTA technique with the other methods may improve the quality of dried wild vegetables. For example, it is worth investigating the effect of the MOTA procedure followed by microwave- assisted drying or the MOTA procedure followed by relative humidity drying.